Last month at the

| "Ama Natura" - Photo courtesy of Capt. Peter Wilcox |

The NOAA green ships program was initiated in 1999, through the NOAA Great Lakes Environmental Research Laboratory (GLERL). Their vessels run on B100, biodiesel derived 100% from soy, a renewable energy source. In addition to the fuel, all of the lubrication and hydraulic products used on these vessels are plant-derived, from soy, rapeseed and canola oils.

Benefits that NOAA has seen from this program are numerous.

Environmental & Social Benefits✦ Decreases emissions of fossil fuels that contribute to climate change and air pollution

✦ Lessens risk of environmental harm in the event of a fuel spill

✦ Reduces dependence on imported oil

✦ Supports agriculture and the U.S. economy

Operational Benefits✦ Improves engine performance

✦ Extends engine life

✦ Reduces need for engine maintenance due to cleaning properties of biodiesel

✦ Reduces operating and maintenance costs by 20-40% vs. petroleum-based fuels

Human Health Benefits✦ Reduces exposure to harmful and cancer-causing chemicals

✦ Reduces seasickness due to less offensive odor

Biodiesel is cleaner than petroleum-based diesel, which is behind many of the benefits. These show in longer lifespan of injectors, fuel pumps and filters, also in reduced or disappearing cleaning costs for tanks, fuel lines and other components of the fuel system.

|

| Washington State ferry "Spokane" runs on biodiesel |

The emissions reductions of biodiesel compared with diesel, as reported by NOAA, are impressive.

✦ Total unburned hydrocarbons -77%

✦ Carbon monoxide -48%

✦ Particulate matter -59%

✦ Nitrogen oxide -7%

✦ Sulfates -74%

✦ Polycyclic aromatic hydrocarbon -66%

Biodiesel can be made from many plant sources, so can be adapted to the most suitable renewable crop or waste material. Used cooking oil can also be filtered and reprocessed to produce biodiesel, for a very cost-effective fuel. GLERL has seen a 20-40% reduction in operating costs on its fleet since converting to biodiesel and other bio products.

For more information on the NOAA program, read the

NOAA Green Ships Initiative.

Biodiesels continue to be developed. Second generation formulations offer longer stability, higher octane ratings and lower waste. Biolubricants are also improving, allowing 100% improvement in oil life.

The NOAA clean ships program appears to be a good one, with major long-term benefits for the world in general and for boaters in particular.

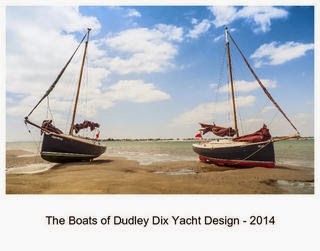

Dudley Dix

I thought of a neat way of adjusting the rake of the centreboard too, which is basically a stevo top rudder gudgeon for the centreboard, that the retainer pin goes through. a thumb screw at the front of the centreboard, just above the deck, pushes a rod back and forth inside the top of the foil and the pin goes through that. the rod would be like 50mm long and is held in there pretty well so the hole in the carbon can be elongated. it means your centreboard case needs to taper slightly, but the range of adjustment is no more than 1 or 2 degrees to accommodate all wind conditions.. just a thought. i think ill be doing that if i build another foil.

I thought of a neat way of adjusting the rake of the centreboard too, which is basically a stevo top rudder gudgeon for the centreboard, that the retainer pin goes through. a thumb screw at the front of the centreboard, just above the deck, pushes a rod back and forth inside the top of the foil and the pin goes through that. the rod would be like 50mm long and is held in there pretty well so the hole in the carbon can be elongated. it means your centreboard case needs to taper slightly, but the range of adjustment is no more than 1 or 2 degrees to accommodate all wind conditions.. just a thought. i think ill be doing that if i build another foil.  ^ i entered the seabreeze.com.au

^ i entered the seabreeze.com.au

Hestur has required very little maintenance over the last year, the biggest thing was to

Hestur has required very little maintenance over the last year, the biggest thing was to

.JPG)